Water ingress

Water is the catalyst or poor fuel quality. Our system removes water by sweeping the entire tank floor and pumps it into a holding tank to settle. Fuel is treated and returned to the UST.

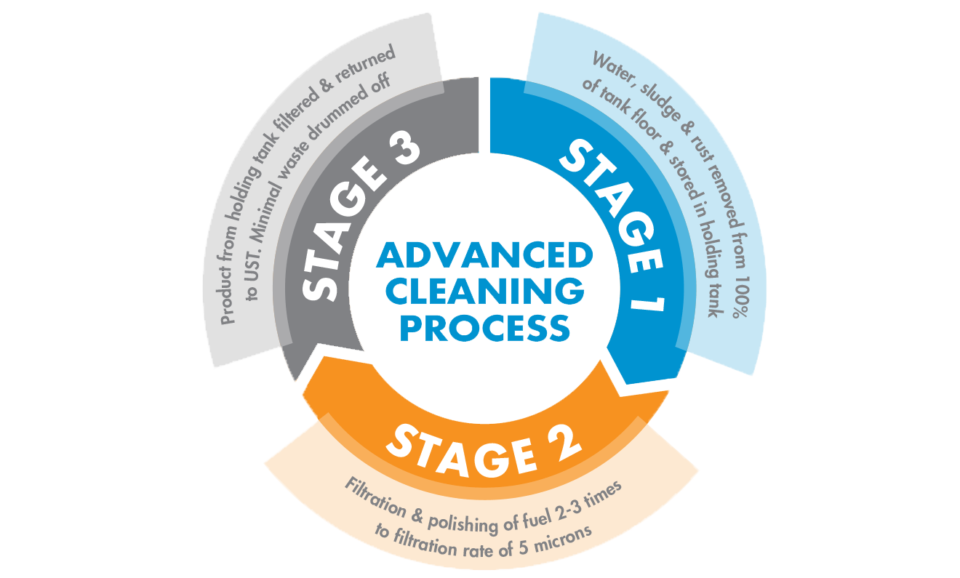

The industry’s most advanced fuel polishing system to restore your fuel and tank back to optimal condition

Poor fuel quality and tank health can have a major impact on your fueling operations. Water and low sulfur fuels create biological growth leading to rapid corrosion of multiple UST system components and equipment.

Our research reveals 36% of USTs have some form of contamination at the bottom of the tank. Moreover, a US EPA study found 83% of ultra-low sulfur diesel tanks showed moderate to severe corrosion – with 25% of tank owners unaware of the problem prior to inspection.

You don’t want to leave it to your customers to complain of engine failure from contaminated fuel or stand at the pump longer than they need to due to slow flowing pumps from clogged filters and malfunctioning equipment.

Leighton O’Brien provides the most comprehensive solution for removing contamination and free water and restoring fuel quality.

Our patented* fuel restoration technology is the industry’s most advanced solution saving you thousands in lost fuel and expensive repairs.

Global fuel retailers trust our best-in-class fuel polishing system to restore phase separated fuel to dry and correct octane levels, address bacterial contamination issues, manage ongoing fuel quality programs and provide fuel sampling to thousands of underground storage tanks.

*US Fuel Cleaning Patent No. 8,753,451

Water is the catalyst or poor fuel quality. Our system removes water by sweeping the entire tank floor and pumps it into a holding tank to settle. Fuel is treated and returned to the UST.

Our solution removes free water and remediates the remaining phase of fuel separation to a saleable condition. The fuel is restored to a refinery specification – saving thousands of dollars in not having to dump your fuel.

Common fuel microbes grow in the water/fuel interface or in sludge on the tank floor. Our system removes 100% of the microbial growth and the environment in which it can flourish, preventing Microbial Influenced Corrosion (MIC).

Our diesel fuel polishing system reconditions and restores aged, degraded diesel from your generator to on-specification fuel giving you peace of mind knowing your back-up generator will work if an emergency strikes.

Read the flyer for USA for c-store and commercial operators

Learn moreRead the flyer for businesses outside of the USA

Learn moreWe have high quality fuel restoration and tank cleaning partners around the world. Use our map to find a partner near you.

Find a partner